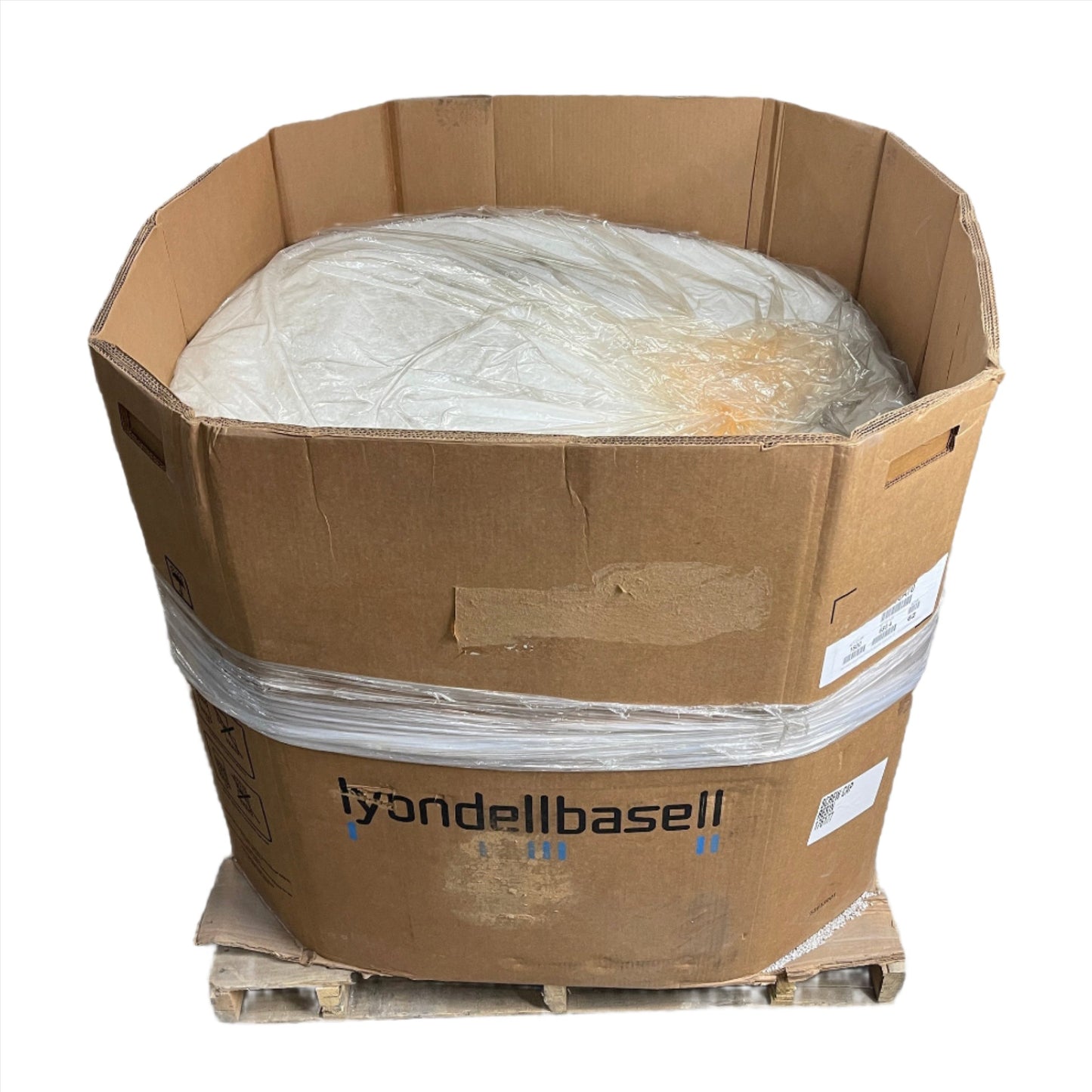

Lyondell Basell

LYONDELL BASELL Pro-Fax SG802N BULK Resin/ Polypropylene Plastic Pellets

LYONDELL BASELL Pro-Fax SG802N BULK Resin/ Polypropylene Plastic Pellets

Regular price

$2,200.00 USD

Regular price

$6,500.00 USD

Sale price

$2,200.00 USD

Unit price

per

Shipping calculated at checkout.

Couldn't load pickup availability

LYONDELL BASELL

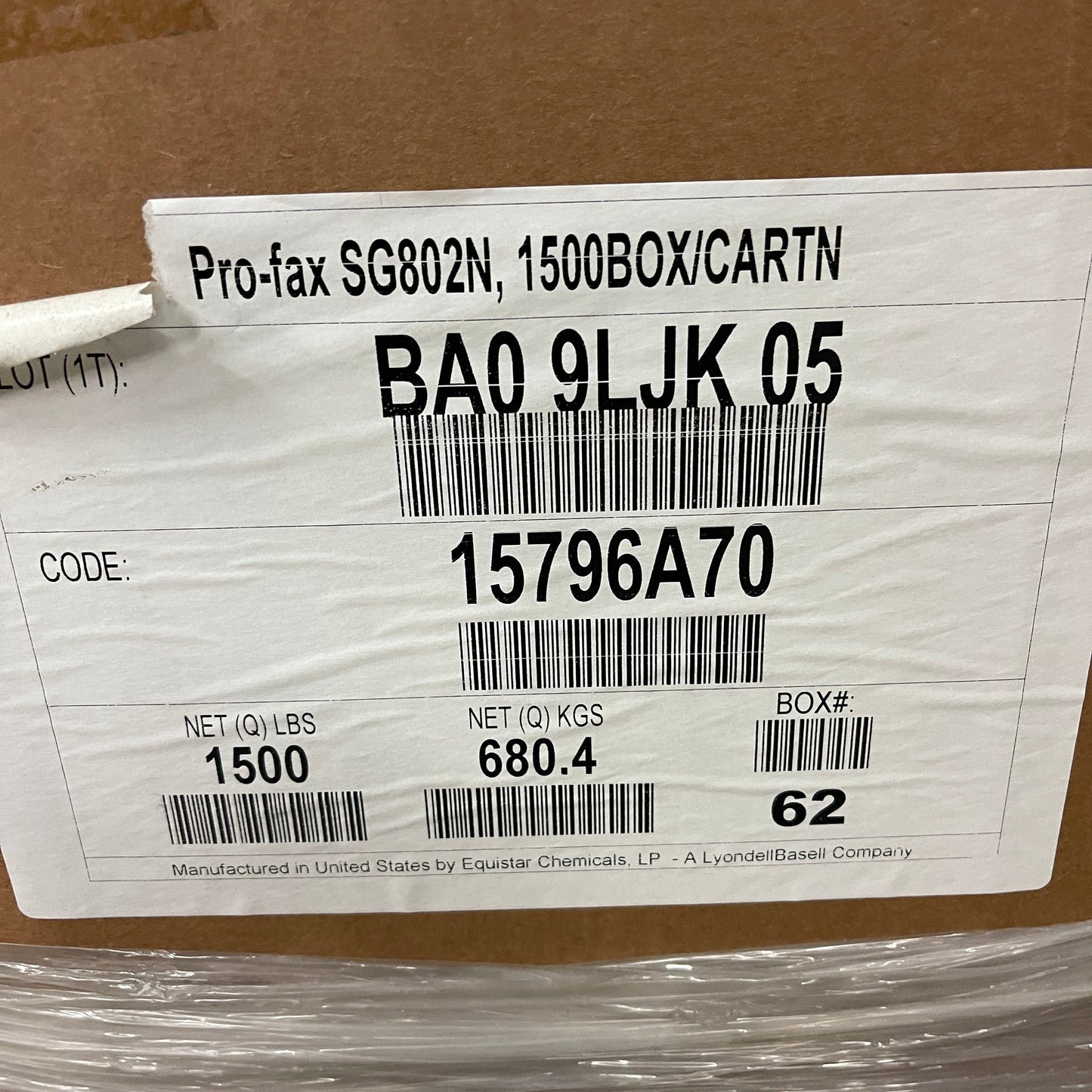

Pro-Fax SG802N

High Impact PolyProplyne CoPolymer Resin

Plastic Pellets for Injection/ Blow Molding

Condition: New

Size: 1500Lbs - BULK

Available in 50 Lb Bags

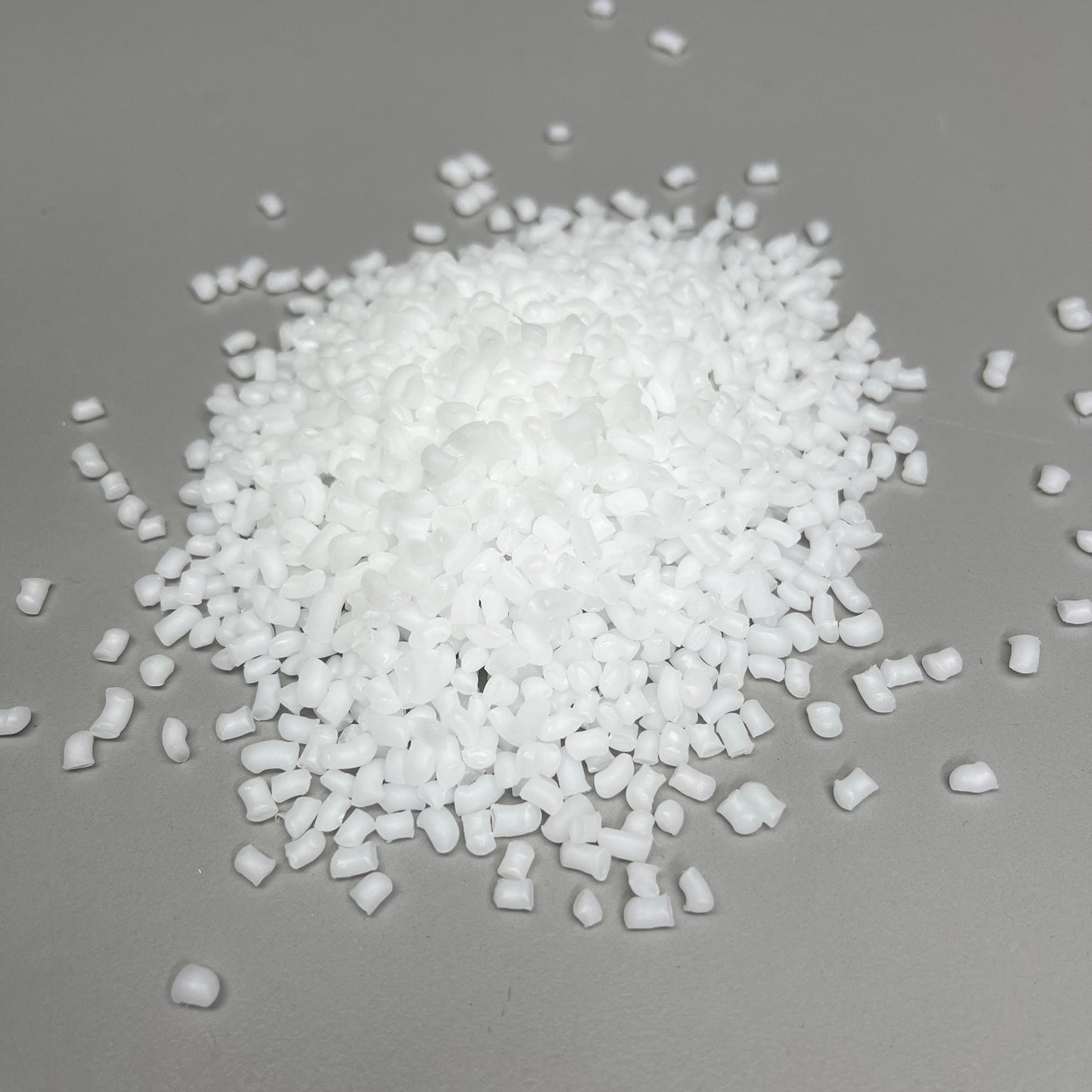

Color: White

MPN / Model: SG802N

Pro-fax SG802N high-impact polypropylene copolymer is available in pellet form.

This resin is typically used in injection molding applications and offers very good cold-temperature impact resistance.

| Categories: |

Polymer; Thermoplastic; Polypropylene (PP)

|

|---|---|

| Material Notes: |

Key Features: high flow, high impact polypropylene copolymer resin, excellent cold impact resistance, good stiffness and impact balance, UV stabilizer compatibility |

Product Data and Technical Information

| Melt Flow Rate (230 °C/2.16 kg) | 35 g/10 min |

| Density (23 °C) | 0.90 g/cm³ |

| Density (23 °C, Method A) | 0.90 g/cm³ |

| Flexural Modulus (23 °C) | 1120 MPa |

| Flexural Modulus (0.05 in/min, 1% Secant, Procedure A) | 160000 psi |

| Flexural Modulus (1.3 mm/min, 1% Secant, Procedure A) | 1100 MPa |

| Tensile Strength at Yield (2 in/min) | 3100 psi |

| Tensile Strength at Yield (50 mm/min) | 21 MPa |

| Tensile Stress at Yield (23 °C) | 21 MPa |

| Tensile Elongation at Yield | 5 % |

| Tensile Strain at Yield (23 °C) | 5 % |

| Charpy Impact Strength - Notched (23 °C) | 11 kJ/m² |

| Charpy Impact Strength - Notched (-30 °C) | 4.5 kJ/m² |

| Notched Izod Impact Strength (23 °C) | 12 kJ/m² |

| Notched Izod Impact Strength (-40 °C) | 5.3 kJ/m² |

| Notched Izod Impact Strength (73 °F, Method A) | 2.3 ft-lb/in |

| Notched Izod Impact Strength (23 °C, Method A) | 123 J/m |

| Deflection Temperature Under Load (66 psi, Unannealed) | 219 °F |

| Deflection Temperature Under Load (0.45 MPa, Unannealed) | 104 °C |

| Deflection Temperature Under Load (0.45 MPa, Unannealed) | 83 °C |

| Deflection Temperature Under Load (1.80 MPa, Unannealed) | 50 °C |

| Mold Shrinkage |

Process

Compounding, Injection Molding

Resin

Polypropylene, Impact Copolymer

Applications

Interior Automotive Applications, TWIM Food Containers, Underhood